IZOFLEX – 58

R

oll SALAMBO® waterproofing membranes are made of modified bitumen with APP / atactic polypropylene / or SBS / styrene butadiene styrene / with different types of tissue basis, with or without terminating coverage depending on their purpose. Available in five basic colors: gray, green, red, melange gray, green and red to black.

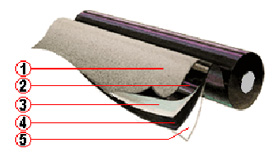

IZOFLEX – 58 - APP:

- Polyethylene film

- APP / atactic polypropylene / - modified bitumen

- Reinforced base layer / glass fiber with reinforced threads in 2 cm./

- APP / atactic polypropylene / - modified bitumen

- Colored mineral slate / shale / or polyethylene film

Application: Waterproofing of flat roofs, pitched roofs, the second top coat for repair of old roofs, first underlay for new roofs, a second top coat for new roofs over thermal insulation.

Benefits:

L

ightweight and flexible, strong and reliable, versatile, with a good aesthetic appearance, a variety of colors and shapes, saving labor and time, require no maintenance, durable.

R

oll waterproofing materials have a wide range of applications. As one layer coating - repair of old roofs, building foundations, basement walls, canals, new roofs, gas tanks for LPG, power substation KTP and others. Complete multilayer systems - for all kinds and types of roofs and engineering facilities / underground tanks, bridges, tunnels, roads, etc. /

T

he choice of the optimal variant of the waterproofing depends on several factors / as technological requirements, mechanical loads, weather conditions, etc. /, And therefore need to be made by a specialist - individually for each case.

IMPORTANT : Waterproofing rolls to be transported and stored vertically. Concrete basis on which to make, be smooth and pre-primed, clean and dry. Do not apply at ambient temperatures below -10 ° C

|

Parameters

|

Test Method

|

Measure

|

IZOFLEX - 58

|

|||||||

|

2 kg/m2 without protective mineral layer

|

2,5 kg/m2 without protective mineral layer

|

3 kg/m2 without protective mineral layer

|

3,5 kg/m2 without protective mineral layer

|

4 kg/m2 without protective mineral layer

|

3,5 kg/m2 with a protective mineral layer

|

4 kg/m2 with a protective mineral layer

|

4,5 kg/m2 with a protective mineral layer

|

|||

|

Type the basis

|

-

|

-

|

Glass veil

|

|||||||

|

Type of bitumen

|

-

|

-

|

Modified: APP

|

|||||||

|

Width

|

BDS ЕN 1848-1

|

cm

|

100

|

100

|

100

|

100

|

100

|

100

|

100

|

100

|

|

Mass per unit of area

|

BDS ЕN 1849-1

|

kg/m2

|

2

|

2,5

|

3

|

3,5

|

4

|

3,5

|

4

|

4,5

|

| Tensile strength at break - longitudinal - cross |

BDS ЕN 12311-1

|

N/5cm

|

472

250 |

400

250 |

475

250 |

485

250 |

480

250 |

450

250 |

523

250 |

455

250 |

| Elongation - longitudinal - cross |

BDS ЕN 12311-1

|

%

|

7

8 |

5

8 |

6

11 |

6

8 |

8

11 |

8

8 |

6

10 |

5

10 |

|

Waterproof under pressure 0,7MRa for 24h

|

BDS ЕN 1928

Method В |

-

|

impervious to water

|

|||||||

|

Flexibility at low temperatures

|

BDS EN 1109

|

°C

|

- 5 °C / - 10 °C without changes

|

|||||||

|

Heat resistance

|

BDS EN 1110

|

°C

|

+ 120 °C without drip

|

|||||||

| Resistance of ripping off the joints - longitudinal - cross |

BDS EN 12316-1

|

N/5cm

|

60

30 |

50

30 |

61

30 |

69

35 |

62

30 |

52

32 |

70

36 |

72

42 |

|

Shear strength of splice

- longitudinal - cross |

BDS EN 12317-1

|

N/5cm

|

(break outside joints)

|

|||||||

|

475

250 |

400

250 |

480

250 |

500

255 |

485

250 |

465

255 |

525

255 |

465

250 |

|||

| Adhesion of mineral pospka (weight loss) |

BDS EN 12039

|

% by weight

|

-

|

-

|

-

|

-

|

-

|

7 ± 0,2

|

5,3 ± 0,2

|

4,4 ± 0,1

|